Our Products

-

Permanent Lifting Magnets

Permadur Electrically Controlled Permanent Magnets will not drop a suspended load due to power failure. faulty wiring, or misoperation of controls. No backup battery system is required and mo power is consumed during the lift.

LEARN MORE -

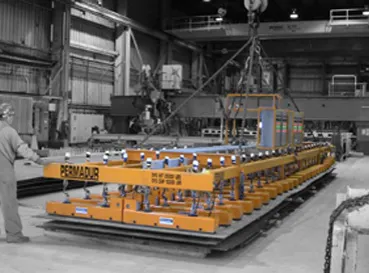

Plate handling magnet systems

Utilizing the performance and safety features of the Permadur Lifting Magnets, these plate handling systems can handle a single plate off of a stack and be operated remotely by crane operator.

LEARN MORE -

Multiple Part Handling Magnet Systems

These systems increase the productivity of your cutting operations by dramatically reducing the material handling time which results in increased Torch "ON" Time

LEARN MORE -

Vacuum lifting systems

Permadur Vacuum Lifting Systems provide a lighter, more economical way of addressing a wide range of Aluminum, SS, and Carbon Steel Plate Handling Applications.

LEARN MORE -

Manually controlled lifting magnets

Permadur's BPM and REM series manual lifting magnets are utilized where there is demand for lifting heavy steel pieces EFFICIENTLY. Machine shops, cutting/saw workstations, and steel service centers will use varying capacities of manual magnets.

LEARN MORE -

Load Positioners

Permadur's Load Positioner is a below the hook lifting and lowering device that is hydraulically operated. It simplifies alignment and assembly as well as reduces the risk of part damage.

LEARN MORE

Service and repair parts

by Permadur’s skilled technicians

Learn moreRoutine Maintenance, reconditioning, and repairs will extend the service life of your lifting magnet or vacuum system. When scheduling your downtime, let Permadur’s skilled Technicians inspect your equipment and recommend the best preventive maintenance program.

What we offer

-

PRECISE MATERIAL HANDLING

For applications where every thousandth of an inch matters.

-

SMARTER LIFTING SYSTEMS

Engineered to lift your loads with safety and efficiency in mind.

-

EXPERT MAINTENANCE & REPAIRS

Our highly skilled technicians keep your operations running smoothly and at optimal capacity.

-

MULTIPURPOSE HANDLING

Providing safety and power to a wide variety of industries and facilities throughout North America

leave the heavy

lifting to us

The time has come to take the next step for your material handling needs. Let us help get what you need.

Recent Posts

- The Most Important Thing to Consider When Choosing a Vacuum Lifting System

- What is a Multiple Part Handling Magnet System?

- Permadur Vacuum Lifting Systems: We Have the Features You Need

- Revolutionizing Material Handling with Permadur's Plate Lifting Magnets

- Permadur's Permanent Lifting Magnet Options: Rectangle & Bipolar

- Things to Consider When Choosing a Permanent Lifting Magnet

- Safety Checklist: Operating an Electrically-Controlled Permanent Lifting Magnet

- Product Spotlight: Permadur Multiple Part Handling Magnet Series 115

- Evaluating Plate Handling, Sheet Handling, and Vacuum Lift Systems

- What Type of Plate Lifting Magnet is Right for Your Business?

- Pros and Cons of Different Lifting Magnets

- Improve Your Sheet Handling Operation With Vacuum Lifting Systems

- Product Spotlight: Permadur Large Plate Vacuum Lifting System Series 114

- Understanding the differences between Permanent lifting Magnets and Vacuum Lifting Systems

- Selecting the Appropriate Permanent Lifting Magnet for Industrial Use