Multiple Part Handling Magnet Systems are innovative solutions that streamline lifting, moving, and separating metallic materials in various industrial environments. These systems utilize the principles of magnetic force to securely grip and handle metal parts without direct physical contact, thereby enhancing safety and efficiency in operations such as manufacturing, metal processing, and recycling. By employing an array of lifting magnets mounted on a sturdy load beam, these systems offer a versatile approach to handling a wide range of metal objects, from large plates to intricate parts. Below are detailed aspects that highlight the functionality and components of these systems:

- Lifting Magnets: Central to the system, these magnets provide the necessary force to lift metal materials safely. The number and capacity of magnets can vary, allowing for customization based on the operation's specific needs.

- Load Beam: This structural element supports the lifting magnets and can be designed to accommodate varying lengths and strengths, depending on the system's intended use and the size of the materials to be handled.

- Control Options: To maximize flexibility and ease of use, these systems are equipped with various control mechanisms, such as radio remote controls and hard-wired pendant controls, enabling precise manipulation of the magnetic lifting process.

- Safety Indicator Lighting System: A crucial feature that offers visual feedback to operators, confirming when magnets have successfully attached to the load, thus enhancing operational safety by mitigating the risk of accidental drops.

- Sling Suspensions and Attachment Options: Designed for seamless integration with existing material handling infrastructure, these systems can be easily attached to single-hook cranes, employing sling suspensions or other mechanisms to ensure stability and safety during lifts.

From the broader concept of Multiple Part Handling Magnet Systems, let's now focus on what Permadur brings to the table. Permadur systems take the principles of magnetic force and apply them in ways that show what's possible when innovation meets industrial needs. Each product in their lineup isn't just about lifting metal; it's about doing so in a way that's smarter, safer, and more suited to the specific demands of today's manufacturing and processing industries. As we explore the distinct features and advantages of each Permadur system, it becomes clear how these tailored solutions are changing the game in metal handling.

Permadur Series 115 Plate/Multiple Part Handling System

- Features: The Series 115 system is equipped with 15 BP-1600x72 Lifting Magnets on a 10-foot load beam, designed with fixed magnets on 8-inch centers. It includes Permadur's exclusive safety indicator lighting system, a skeleton picker frame assembly for parts/skeleton separation, and options for radio control or hard-wired pendant controls for operational flexibility.

- Strengths: This system's strength lies in its ability to efficiently handle multiple parts with a focus on safety and flexibility. Including a skeleton picker frame assembly benefits industries where parts and waste materials must be separated and handled distinctly.

- Best Applications: Ideal for manufacturing environments requiring precise material handling and separation, such as automotive or metal fabrication industries. The safety and selectivity features ensure it is suited for applications where operator control and safety are paramount.

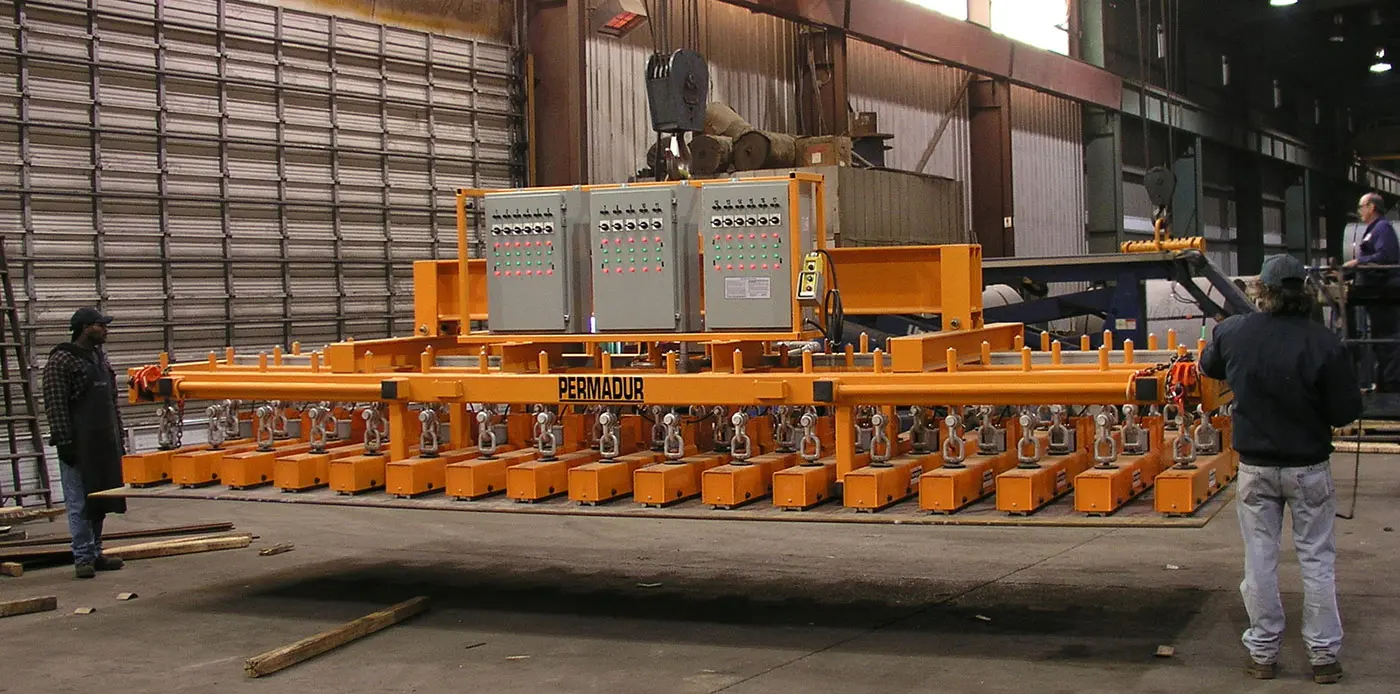

Permadur Series 2550 Plate/Multiple Part Handling System

- Features: This robust system boasts 50 BP-1600 Lifting Magnets on a 30-foot load beam, providing extensive control with selectivity by magnet row and individual magnets. It supports many control options, including radio and pendant controls, and features a 6-part sling suspension for crane attachment.

- Strengths: The Series 2550's capacity for handling large volumes of material with precise control makes it a powerhouse in the Permadur lineup. Its extensive control options and safety features, like the exclusive safety indicator lighting system, ensure high efficiency and operational safety.

- Best Applications: Best suited for heavy industrial settings requiring the lifting of large loads, such as steel mills or shipbuilding yards. Its large capacity and robust control options make it ideal for operations that demand high efficiency and flexibility in material handling.

Permadur Series 1530 Plate/Multiple Part Handling System

- Features: The Series 1530 system features 30 BP-1600x48 Lifting Magnets on a 10-foot load beam, with selectivity by magnet row and individual magnets. It includes radio controls and hard-wired pendant controls, along with a 4-part sling suspension for crane attachment.

- Strengths: The Series 1530's combination of selectivity and safety features, including Permadur's safety indicator system, positions it as a versatile and reliable solution for medium-scale material handling needs. The system is designed for safety and efficiency and accommodates various industrial applications.

- Best Applications: This system is well-suited for medium-sized operations in industries like construction or heavy machinery manufacturing, where precise control over material handling is necessary. Its balance of power and control ensures adaptability across various material handling scenarios.

Permadur Series 1326 Plate/Multiple Part Handling System

- Features: Equipped with 26 BP-1600x48 Lifting Magnets on a 20-foot load beam, the Series 1326 includes a 4-part sling for crane attachment and features selectivity by row with individual safety indicator lights. The system also provides plate grabs for part/skeleton separation.

- Strengths: The Series 1326 excels in providing operational flexibility with a strong emphasis on safety. Its design facilitates the lifting and efficient separation of materials, enhancing workflow in material processing tasks.

- Best Applications: This device is ideal for handling and separating parts and materials, such as in metal processing or recycling facilities. Its added feature of plate grabs makes it particularly useful in environments where material reuse and efficiency are critical.

Permadur Series 714 Plate/Disc/Skeleton Handling System

- Features: This system includes 14 TP-2000 Lifting Magnets on a 25-foot load beam, with manual repositionability for each magnet. It offers unique control options, including three ON modes for different handling needs, and attaches to cranes via a 4-part sling.

- Strengths: The Series 714 stands out for its manual adjustability and specialized control modes, offering unparalleled versatility for handling discs, plates, and skeletons. Its flexibility in operational modes allows for tailored handling processes, ensuring efficient material processing.

- Best Applications: Specifically designed for industries that deal with various material shapes and types, such as metalworking or manufacturing facilities that process raw materials and finished goods. Its manual adjustability and specific control modes suit niche applications requiring customized handling solutions.

Each Permadur system offers unique benefits tailored to different industrial applications, showcasing a range of capabilities from high-capacity lifting to specialized material processing and separation.

Related Reading

- Permadur Vacuum Lifting Systems: We Have the Features You NeedVacuum lifting systems are engineered to enhance operational efficiency, safety, and versatility across diverse industrial applications.

- Evaluating Plate Handling, Sheet Handling, and Vacuum Lift Systems

- Understanding the differences between Permanent lifting Magnets and Vacuum Lifting Systems