What is Magnet Pull Force in Plate Lifting Magnets?

Magnet pull force is required to pull a magnet away from a ferromagnetic material, typically a steel plate, in a vertical direction. This force is usually quantified in pounds or kilograms and is a critical indicator of the magnet's maximum holding capacity. The pull force is significant because it reflects the magnet's ability to hold onto a ferromagnetic material under ideal conditions.

Why Does Pull Force Matter for Plate Lifting Magnets?

Pull force matters significantly as it directly influences the practical applications and safety of using magnets in various industries. A higher pull force signifies a stronger magnet capable of holding more substantial weights. For instance, a thorough understanding of the pull force in lifting operations is crucial to selecting the appropriate magnet, ensuring safety and efficiency. It is pivotal in preventing accidents caused by magnets failing to hold heavy objects securely.

Factors Influencing Magnet Pull Force

Several factors influence the pull force of a magnet, making it a complex parameter to measure accurately. These factors include:

- Magnet Strength: The magnetic strength, often measured in Tesla, directly correlates with pull force. Stronger magnets exhibit higher pull forces.

- Size and Shape: Larger magnets generally have higher pull forces due to their increased surface area in contact with the steel plate.

- Orientation: The pull force is highest when the magnet is perpendicular to the ferromagnetic material. As the angle increases, the pull force decreases.

- Air Gap: Any gap, such as paint, rust, or grease, between the magnet and the steel surface can significantly reduce the pull force.

- Surface Conditions: The condition and composition of the steel surface, including thickness and coatings, also affect the pull force.

Horizontal vs. Vertical Applications

The pull force, often measured in ideal conditions, is typically associated with vertical applications. However, magnets are frequently used in horizontal applications, such as attaching to a refrigerator door in real-life scenarios. In these cases, the effective holding force, known as the shear force, is considerably lower than the vertical pull force due to the additional friction and gravitational forces acting on the magnet.

Choosing the Right Magnet

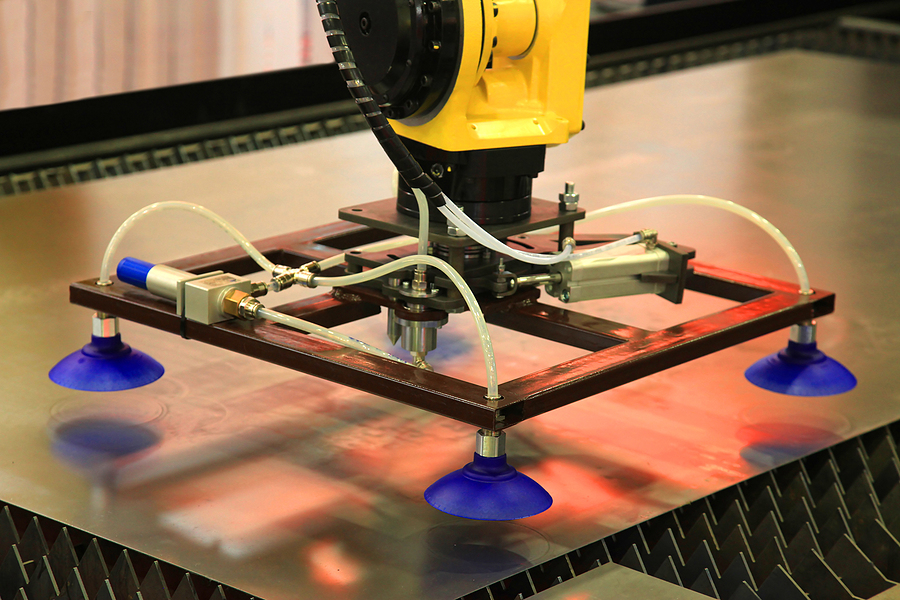

Understanding the pull force of a magnet and how it interacts with the environment is not just theoretical knowledge. It has practical implications for safe and efficient operations. Testing the magnet in the actual application is crucial because theoretical values may not account for real-world variables like surface conditions and air gaps. Considering a safety margin, ensuring the magnet's pull force is sufficient for the intended load is essential for safe operations.

Practical Tips for Safe and Effective Magnet Use

Everyday users of lifting magnets can follow these best practices to ensure safe and effective lifting.

- Understand the Rated Lifting Weight: Always use the magnet within its rated lifting weight, which is lower than its maximum pull-off force to ensure safe operations.

- Minimize Air Gaps: Contact surfaces must be clean to maximize the pull force. They should have no debris, rust, or coatings.

- Proper Orientation: Use the magnet perpendicular to the load for maximum efficiency.

- Regular Maintenance: Regularly inspect and maintain magnets and contact surfaces to prevent degradation of the pull force.

- Safety Factor: Apply a safety factor, typically three times the object's weight, to account for unforeseen variables and ensure secure lifting.

Getting Optimal Performance from Plate Lifting Magnets

As professionals in plate lifting magnets, understanding these concepts and implementing best practices is in our hands. By doing so, we can maximize the effectiveness and safety of magnets in various lifting and holding applications.