Permadur Multiple Part Handling Systems

Maximize torch-on time

Permadur Multiple-Part Handling Magnet Systems are designed to significantly reduce material handling time in plasma cutting and steel processing operations. By lifting cut parts and skeletons in a single pick, these systems increase torch "ON" time, improve throughput, and lower operating costs for steel fabricators and steel service centers.

Instead of manually separating parts or making multiple lifts, operators can safely handle more material at once — reducing labor, improving safety, and keeping production moving.

How It Works

Permadur systems use high-density magnet configurations mounted to custom load beams to securely lift multiple parts or skeletons at the same time. Selective magnet controls and movable cross arms allow operators to target specific areas of the plate, making part separation and removal faster and more controlled.

Once engaged, the magnets hold the load mechanically and do not rely on continuous power during the lift, providing stable and predictable handling even in demanding production environments.

Key Benefits

- Increases plasma table productivity by reducing offload time

- Allows removal of parts and skeletons in a single lift

- Reduces manual labor and operator fatigue

- Improves safety and minimizes dropped or shifting loads

- Boosts torch "ON" time for higher overall throughput

Engineered for Safety & Reliability

- Designed and built to OSHA and ASME B30.20 standards

- Engineered to the appropriate safety factor for your specific application

- Positive on/off indication with operator feedback lights

Will not drop a suspended load due to:

- Loss of electrical power

- Faulty wiring

- Misoperation of controls

Features & Capabilities

Typical Applications

- Plasma and oxy-fuel cutting tables

- Fabrication shops and steel service centers

- High-volume plate processing operations

- Facilities seeking reduced handling time and increased throughput

The Result

With Permadur Multiple-Part Handling Magnet Systems, shops move more material with fewer lifts and fewer operators. Handling becomes safer and more predictable, material damage is reduced, and productivity increases across every shift.

Get a Custom Solution for Your Cutting Table

Request a quote or contact our sales team to discuss your cutting table, plate size, and part-handling requirements.

Product Description

Overview

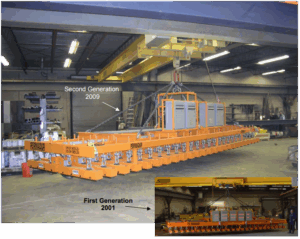

Permadur Multiple Part Handling Magnet Systems increase the productivity of your Plasma Cutting Operations by dramatically reducing the Material Handling time required to offload Cut Parts and Skeleton. Reduced material handling time results in increased Torch “ON” Time, which means higher productivity and lower costs for both Steel Fabricators and Steel Service Centers.

Magnet Systems can help you to decrease hours of physical labor, reduce handling time, all while performing in a safe environment. Call us today.

Key Benefits

- High-density magnet configurations optimize efficiency

- Will not drop load due to power loss, faulty wiring or misoperation of controls

- Selective magnet controls with movable cross arms

- Built to OSHA and ASME 830.20 standards

- No power consumption during lift (100% duty cycle)

- Control options range from ON/OFF pushbutton to radio remote to PLC controls. Permadur controller provides safety indicator lights for positive feedback to the operator to confirm magnet attachment prior to lift

- Skeleton picker frames simplify part separation

- Lower head room design

- Single sheet lift from stack

Models

Custom design based on plate size and part sizes to be removed from the burning table in a single lift.

Use Cases

For fabrication shops and steel processors seeking higher throughput and reduced downtime.

Features

SERIES

Media

Click to view full-size images.

Related From our Blog

Understanding How The Mining Industry Uses Industrial Magnets

The mining industry is one of many industries that rely on industrial magnets. While there are...

Safety and Proper Use of An Industrial Neodymium Magnet

Neodymium magnets are extremely useful for industrial-scale lifting and are relied upon in many...

How to Properly Operate A Heavy Lifting Device

Operating heavy lifting devices is a serious business. There are many moving parts and hazards to...

Problem / Cause / solution / benefit

Problem

In many fabrication shops, warehouses, and industrial operations, handling multiple parts at once — such as bundles of sheet metal, stacked plates, grouped components, or sets of similar parts — is inefficient, risky, and labor-intensive. Using slings, chains, clamps, or manual means to lift multiple items often leads to uneven loads, material damage, mis-handling, longer cycle times, and increased chance of operator injury or dropped parts.

Cause

Because conventional lifting and rigging methods are designed for single-part loads, attempts to lift multiple parts together rely on makeshift solutions: awkward placement of slings or clamps, uneven weight distribution, repeated manual adjustments, and reliance on multiple operators. This leads to slow setup times, inconsistent load security, potential damage to parts (scratches, bends), and increased safety risks — especially when loads shift or are imbalanced. Additionally, manual handling becomes a bottleneck as throughput needs increase.

Solution

Permadur’s Multiple-Part Handling Systems provide engineered lifting/handling solutions designed to safely, securely, and efficiently lift and transport groups of parts as a unit. These systems are tailored to accommodate bundled, stacked, or multiple-part loads — ensuring balanced lifting, stable rigging, and secure transport. By using purpose-built hardware instead of improvised rigging, these systems allow one operator (or fewer operators) to lift and move multiple items at once with proper load distribution, minimal manual readjustment, and reduced risk of part damage or load shift.

Benefit

Using Permadur Multiple-Part Handling Systems dramatically improves efficiency, safety, and throughput. Operations complete lifts faster and with fewer workers, reducing labor costs and time per lift. Material quality is preserved — fewer scratches, bends, or dropped parts — lowering scrap and rework. Safety improves through more stable, predictable lifts, reducing risk of operator injury or accidents. Overall workflow becomes more streamlined: higher volume and speed per shift, lower damage rates, reduced labor overhead — delivering better productivity and cost-effectiveness for handling grouped loads.