Lifting Solutions

Permadur Industries Inc. serves a wide range of industries with tailor-made lifting solutions designed for safe, efficient material handling. Our systems are engineered to handle everything from steel plate, beams and structural shapes to aluminum, titanium, plastics, acrylic, wood, cardboard, and composite materials. Explore the core industries we serve and see how we’ve increased safety, productivity, and overall operational efficiency across their facilities.

Lifting Solutions by Material Type

< Swipe to Navigate >

Lifting & Positioning Solutions for Steel Plate and Structural Steel

Steel Plate and Structural Steel

Typical Loads

Carbon steel plate, heavy plate, wide-flange beams, channels, angles, HSS sections, and other structural shapes in a wide range of sizes, thicknesses, and weights. Materials may be handled individually or in staged groups depending on workflow and processing requirements.

Recommended Permadur Solutions

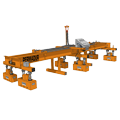

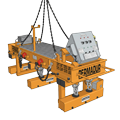

- Plate Handling Systems – Designed for lifting single plates from a stack and safely transporting large flat material with controlled, stable handling.

- Multiple-Part Handling Systems – Ideal for removing cut parts or skeletons from plasma or oxy-fuel cutting tables in a single lift.

- Strip Handling Systems – Well suited for lifting cut strips, structural shapes, and plate-and-strip combinations directly from the cutting table.

- Individual Lifting Magnets – Flexible solutions for handling beams, channels, angles, and single plates across a variety of applications.

- Vacuum Lifting Systems – Recommended when surface protection is critical or when handling thin plate where magnetic lifting may not be ideal.

- Load Positioners – Provide precise alignment and controlled placement of long or heavy members during fabrication, welding, or assembly.

Common Tasks

De-stacking plate from storage, offloading material from trucks or rail, feeding burn tables and saw lines, staging beams and structural members for fabrication, removing cut parts and strips, rotating and aligning components for welding, and positioning material for cutting, machining, or processing.

ROI & Operational Benefits

Reduced manual rigging and handling time, faster lift-and-load cycles, increased machine uptime and torch-on time, improved operator safety when handling heavy or awkward loads, and consistent lifting performance supported by engineered systems designed for safety and compliance.

Real-World Impact

By using a Permadur material handling system, structural steel fabricators improve material flow from storage to processing while reducing manual rigging and handling time. Operators are able to move plate, strips, and structural members more efficiently, resulting in faster throughput, improved safety, and a more consistent workflow across daily operations.

Lifting & Positioning Solutions for Aluminum

Aluminum

Typical Loads

Aluminum plate, sheet, extrusions, billets, bars, and fabricated components in a wide range of sizes and thicknesses. Loads often include thin or large-format plate, lightweight but high-surface-area parts, and finished or semi-finished aluminum products that require careful handling and surface protection.

Recommended Permadur Solutions

- Vacuum Lifting Systems – Ideal for non-ferrous aluminum plate and sheet, providing secure, non-marking handling with configurable pad layouts to evenly distribute load and protect surface finishes.

- Load Positioners – Provide controlled movement, precise alignment, and accurate placement of aluminum components during fabrication, assembly, and installation.

Common Tasks

De-stacking aluminum sheet and plate, loading laser and waterjet cutting tables, transferring material between machining and fabrication stations, positioning components for welding or assembly, and staging finished aluminum products for packaging or shipment.

ROI & Operational Benefits

Protection of surface finishes through non-contact lifting, reduced risk of deformation on thin materials, faster machine loading and improved material flow, enhanced operator safety through ergonomic handling, and consistent positioning that reduces rework and scrap.

Real-World Impact

By using a Permadur material handling system, aluminum fabricators improve material flow, protect finished surfaces, and reduce manual handling. Operations benefit from faster changeovers, safer lifting, and improved overall efficiency without increasing labor requirements.

Lifting & Positioning Solutions for Stainless Steel

Stainless Steel

Typical Loads

Stainless steel plate, sheet, bars, and fabricated components in a wide range of grades and thicknesses. Loads often include flat or formed parts where surface finish, cleanliness, and material integrity are critical throughout handling and processing.

Recommended Permadur Solutions

- Vacuum Lifting Systems – Ideal for handling stainless steel plate and sheet, especially non-magnetic or low-permeability grades, providing secure, non-marking lifting while protecting surface finishes.

- Load Positioners – Provide controlled movement, precise alignment, and accurate placement during fabrication, welding, and finishing operations.

Common Tasks

De-stacking sheet and plate, loading laser or plasma cutting tables, positioning material for welding and fabrication, handling finished components without surface damage, and staging parts for polishing or assembly.

ROI & Operational Benefits

Improved protection of surface finishes, reduced risk of contamination or marring, safer handling of heavy or slippery material, faster processing and changeovers, and more consistent positioning that lowers rework and scrap.

Real-World Impact

By using a Permadur material handling system, stainless steel fabricators improve surface protection, streamline material flow, and reduce manual handling. The result is faster machine loading, safer operations, and improved quality throughout downstream finishing processes.

Lifting & Positioning Solutions for Alloys

Alloys

Specialty alloy plate, bars, billets, forgings, and custom-shaped components, including high-strength, heat-resistant, and corrosion-resistant materials used in demanding industrial applications. Loads often vary in size, weight, magnetic response, and surface condition.

Recommended Permadur Solutions

- Vacuum Lifting Systems – Ideal for non-ferrous alloys or applications where surface protection is critical, providing secure, non-marking handling for flat or irregular shapes.

- Individual Lifting Magnets – Suitable for ferrous alloy materials with sufficient magnetic response, offering flexible and efficient handling of bars, billets, and components.

- Load Positioners – Provide controlled movement, precise alignment, and accurate placement for alloy components during machining, inspection, or assembly.

- Custom-Engineered Handling Solutions – Designed to accommodate mixed materials, irregular geometries, variable weights, and unique process requirements.

Common Tasks

Handling raw alloy stock, positioning material for machining or heat treatment, transferring parts between workstations, aligning components for precision operations, and staging finished parts for inspection or assembly.

ROI & Operational Benefits

Safer handling of high-value materials, reduced risk of damage or deformation, fewer manual lifts, improved workflow efficiency, and greater control during precision handling and placement.

Real-World Impact

By using a Permadur material handling system, manufacturers working with specialty alloys gain safer, more controlled handling of complex and high-value materials. The result is improved material flow, reduced handling-related damage, and lower operator strain across demanding production environments.

Lifting & Positioning Solutions for Plastics

Plastics

Typical Loads

Plastic sheets, panels, molded components, composite boards, and lightweight fabricated parts in varying thicknesses and surface textures.

Recommended Systems

Vacuum Lifting Systems with soft, configurable pad materials for non-marking handling; Lightweight lifting frames designed for large-format plastic sheets; Load Positioners for precise placement during cutting or fabrication.

Common Tasks

De-stacking plastic sheets, loading CNC routers or cutting tables, positioning panels for fabrication, and staging finished components for assembly or packaging.

ROI Points

Protection of delicate surfaces, reduced manual handling, improved accuracy when positioning large sheets, faster cycle times, and safer operations when handling flexible or oversized materials.

Case Study

A plastics processor adopted vacuum lifting systems to handle large-format sheets, reducing handling time and minimizing surface damage during cutting and fabrication.

Lifting & Positioning Solutions for Acrylic

Acrylic

Typical Loads

Acrylic sheets, panels, display components, and finished products requiring careful handling to preserve clarity and surface finish.

Recommended Systems

Vacuum Lifting Systems with low-mark, high-hold pads designed for smooth surfaces; Adjustable pad configurations to accommodate varying sheet sizes and thicknesses; Precision positioners for controlled placement.

Common Tasks

Handling and staging acrylic sheets, loading laser cutting or routing equipment, positioning panels for fabrication, and transferring finished parts without scratching or cracking.

ROI Points

Reduced surface damage and breakage, improved handling precision, faster processing of delicate materials, and safer operations with minimal manual contact.

Case Study

An acrylic fabrication facility implemented vacuum lifting solutions to reduce breakage and surface defects, resulting in higher yield and more consistent finished products.

Lifting & Positioning Solutions for Cardboard

Cardboard

Typical Loads

Corrugated cardboard sheets, cartons, stacked blanks, and packaging materials in bulk quantities or large formats.

Recommended Systems

Vacuum Lifting Systems optimized for porous materials; Multi-pad configurations for stable lifting of large or flexible sheets; Lightweight frames for high-speed handling.

Common Tasks

De-stacking cardboard blanks, feeding die-cutting or converting equipment, staging packaging materials, and transferring stacks between production areas.

ROI Points

Increased throughput in high-volume operations, reduced manual labor, consistent feeding into downstream equipment, and improved worker ergonomics.

Case Study

A packaging operation improved line efficiency by integrating vacuum lifting systems, enabling faster material handling and reducing operator fatigue during high-volume production.

Typical Loads

Wood panels, plywood sheets, MDF, lumber, and fabricated wood components in various sizes and thicknesses.

Recommended Systems

Vacuum Lifting Systems for flat wood products; Configurable pad layouts to handle porous and textured surfaces; Load Positioners for precise alignment during cutting or assembly.

Common Tasks

De-stacking wood panels, loading CNC routers or saws, positioning material for fabrication, and staging finished components for assembly or shipping.

ROI Points

Reduced manual lifting of heavy panels, improved accuracy in material placement, faster machine loading, safer handling of large or awkward pieces, and improved workflow consistency.

Case Study

A wood fabrication shop adopted vacuum lifting systems to streamline panel handling, improving safety and productivity while reducing physical strain on operators.

Wood

Lifting & Positioning Solutions for Wood

Lifting Solutions by Core Industries Served

< Swipe to Navigate >

Steel Service Centers & Fabrication

High-volume plate and structural steel handling

Industry Overview

Permadur supplies engineered lifting and material handling systems for steel service centers and fabrication operations that move large volumes of plate, cut material, and structural steel. Our solutions are designed to support continuous production environments where reliability, safety, and throughput are critical.

Common Materials & Components

Carbon steel plate, cut strips, beams, angles, rounds, and staged bundles across a wide range of sizes and thicknesses.

Typical Applications

De-stacking plate bundles, offloading inbound material, feeding burn tables, removing cut parts and skeletons, staging material for processing, and positioning components for fabrication and welding.

Recommended Permadur Solutions

- Plate Handling Systems

- Multiple-Part Handling Systems

- Strip Handling Systems

- Individual Lifting Magnets

- Vacuum Lifting Systems where surface protection is required

- Load Positioners for controlled alignment and placement

Operational Benefits

Reduced manual handling, faster lift-and-load cycles, increased torch-on time, fewer changeovers, improved operator safety, and consistent performance supported by engineered systems and documentation.

Structural Steel Fabrication

Typical Loads

Plates, beams, angles, rounds, and fabricated structural shapes used in construction and industrial frameworks.

Recommended Systems

Plate Magnets; Vacuum Systems for specialty materials; Load Positioners for fit-up and welding accuracy.

Common Tasks

Moving structural pieces from storage to weld bays, aligning parts for welding, lifting cut sections, and transferring assemblies.

ROI Points

Shorter staging times, improved weld alignment, fewer rigging steps, safer handling of long or heavy shapes.

Case Study

A fabrication shop reduced part-to-weld time significantly by converting from chain slings to controlled magnetic lifting.

Metal Fabrication

Typical Loads

Sheet metal, plate stock, cut parts, formed components, and both ferrous and non-ferrous materials depending on application.

Recommended Systems

Vacuum Lifting Systems for non-magnetic metals; Plate Magnets for ferrous materials; Multiple-Part Handling systems for batch moves.

Common Tasks

Loading laser/plasma tables, transferring sheets to press brakes, picking cut parts, stacking and unstacking components.

ROI Points

Faster machine changeovers, reduced risk of part damage, lower operator fatigue, consistent handling for high-volume operations.

Case Study

A metal fabrication facility achieved faster laser table turnover and fewer damaged sheets after adopting vacuum-assisted lifting.

Heavy Equipment & Industrial Manufacturing

Large welded structures and heavy assemblies

Industry Overview

Heavy equipment manufacturers require controlled handling of large plates, welded frames, and oversized assemblies throughout fabrication and assembly. Permadur systems support safe movement, accurate positioning, and efficient material flow in high-load environments.

Common Materials & Components

Large plate, welded frames, heavy assemblies, irregular components, and oversized structural sections.

Typical Applications

Transferring welded structures between workstations, rotating assemblies for welding or inspection, positioning frames for machining or drilling, and staging components for final assembly.

Recommended Permadur Solutions

- Plate Handling Systems

- Multiple-Part Handling Systems

- Individual Lifting Magnets

- Vacuum Lifting Systems for non-magnetic assemblies

- Load Positioners for large-scale alignment

Operational Benefits

Reduced reliance on manual rigging, improved safety, shorter transfer times, increased placement accuracy, and smoother assembly-line flow.

Shipyards & Infrastructure

Marine fabrication and large-scale structural construction

Industry Overview

Shipyards and infrastructure manufacturers handle large plate and structural components in demanding environments. Permadur lifting systems provide controlled, repeatable handling that improves safety and efficiency during hull fabrication and large structural assembly.

Common Materials & Components

Hull plates, curved sections, structural beams, large frames, and specialty alloys.

Typical Applications

Moving plate from storage to cutting operations, positioning hull plates for welding, staging large structural components, and transferring sections during assembly.

Recommended Permadur Solutions

- Plate Handling Systems

- Multiple-Part Handling Systems

- Individual Lifting Magnets

- Vacuum Lifting Systems

- Load Positioners for hull and structural fit-up

Operational Benefits

Reduced dependence on slings and hooks, faster transitions from cutting to fit-up, improved alignment accuracy, and reduced labor exposure during heavy lifts.

Rail & Transportation Manufacturing

Railcars, locomotives, and long structural members

Industry Overview

Permadur provides lifting solutions for rail and transportation manufacturers handling large plates, frames, and heavy sub-assemblies where alignment, repeatability, and safety are essential.

Common Materials & Components

Chassis plates, sidewall panels, roof sheets, beams, welded sub-assemblies, and large housings.

Typical Applications

Unloading raw plate, positioning large sections for welding, staging parts for machining, handling completed sub-assemblies, and aligning major components during assembly.

Recommended Permadur Solutions

- Plate Handling Systems

- Multiple-Part Handling Systems

- Individual Lifting Magnets

- Vacuum Lifting Systems

- Load Positioners for car-body and frame alignment

Operational Benefits

Lower rigging labor requirements, faster move-to-station times, improved alignment consistency, safer handling of heavy components, and more predictable production output.

Aerospace & Defense

Precision handling for regulated environments

Industry Overview

Permadur supplies engineered lifting solutions for aerospace and defense manufacturing where precision, repeatability, and surface protection are required to meet strict quality and compliance standards.

Common Materials & Components

Precision plates, structural components, assemblies, and surface-sensitive or high-value parts.

Typical Applications

Positioning components for machining or assembly, handling finished parts without surface damage, staging assemblies for inspection, and controlled placement during fabrication.

Recommended Permadur Solutions

- Vacuum Lifting Systems

- Load Positioners

- Custom-Engineered Handling Solutions

Operational Benefits

Improved surface protection, precise positioning, reduced rework, safer handling of critical components, and consistent performance in controlled manufacturing environments.

Telecommunications & Tower Manufacturing

Tower sections, long members, and infrastructure components

Industry Overview

Permadur supports telecommunications and tower manufacturers fabricating long structural members, tower sections, and infrastructure components. Our systems are designed to handle plate, cut strips, and long profiles with control and repeatability.

Common Materials & Components

Tower sections, steel plate, cut strips, angles, rounds, tubular components, frames, and fabricated structural parts.

Typical Applications

Moving plate to cutting and bending operations, lifting cut strips and long members from burn tables, positioning sections for welding or bolt-up, and transferring assemblies between workstations.

Recommended Permadur Solutions

- Plate Handling Systems

- Strip Handling Systems

- Multiple-Part Handling Systems

- Individual Lifting Magnets

- Vacuum Lifting Systems for specialty components

- Load Positioners for precision alignment and fit-up

Operational Benefits

Faster handling of long components, reduced manual rigging, improved fit-up accuracy, safer lifts, and more efficient assembly progression